![]()

Imagine the weight of 200 automobiles sitting on a wristwatch-and it keeps on ticking.

Such is the strength of the new ceramic created at Michigan Tech.

Professor Bill Predebon of the mechanical engineering-engineering mechanics department discusses what first flagged him that they had something special.

"We couldn't fracture it," he says, referring to the battery of strength and sudden-impact lab tests to which they subjected the material. He then reveals the dense white disc, two inches in diameter and three-eighth inches thick.

"It's truly a breakthrough."

Since word of the ceramic, or aluminum oxide (Al2O3: "alumina" in the business), has appeared worldwide in professional journals (most recently Mechanical Engineering) and news vehicles (London Financial Times, Business Week), nearly 200 organizations have expressed interest in it for products as diverse as spinal implants, microwave transmission, and filing horses' teeth.

(The departmental secretary comments that Predebon needs his own secretary just to handle all the calls. On this particular day, his desk was littered with phone messages from yet more interested parties.)

"On one hand, our research is fundamental: we want to know why the material is as strong as it is," Predebon says. "Because, if we do, we could either do better, or we can apply it to other ceramics. It is crucial to keep pushing ahead the frontiers in this area."

As for practical applications, that's where the students are helping.

Student Carlos Alonzo is creating a cutting-tool prototype with silicon-carbide whiskers (the industry favorite) imbedded in the MTU alumina.

"The alumina they use commercially in the cutting tools is 50 percent weaker than ours," Predebon says. "If we can imbed those whiskers in our material and maintain our strength, we could have a significant impact in that potential market."

Scaling-up of the process beyond the lab is also crucial, and Predebon says that the Idaho National Engineering Laboratory is interested in doing just that. The result will be a ten-inch diameter specimen finding its way around the globe to potential users.

The designer alumina has come a long way from its less-elegant cousin, which is used as an insulator on telephone poles and spark plugs.

"One secret to our success is that we start with a high-purity, submicron [10-6m]-particle-size powder from which we make the alumina," Predebon says. "We now want to look at nanophase [10-9m] particles and see how that effects it."

This newer creation is more than tough enough.

"The new alumina's unique in its toughness: the ability to inhibit crack growth, and some plasticity," Predebon says.

Why?

"We don't add any additives when creating the alumina," says Professor Bruce Pletka of metallurgical and materials engineering. "Other people typically add oxides to control the grain growth [and maintain strength]. We wanted to start with something more pure."

PhD student Jim Staehler worked two years to determine the pressure, temperature, and time conditions to get the high-strength properties in an alumina pure enough, with the proper grain structure.

Pletka says that, when trying to understand something at the fundamental level, you want to eliminate as many variables as possible, which began the pure alumina scenario.

They actually just wanted to create their own material instead of buying it commercially, and the resulting strength was "really a case of serendipity. People initially didn't believe us. They thought we were full of baloney, until they started breaking their own anvils."

"We really had no idea that we would get the kind of strengths that we did."

Proving the alumina was indeed twice as strong as other similar compounds, Predebon said colleagues at Washington State University, "took our processing scheme and made it on their own, and demonstrated its extremely high dynamic tensile strength and published it."

The alumina also exhibits good dynamic properties: it has great potential to withstand impacts, thus opening even more possibilities to uses such as armor plating of vehicles.

All this analysis of materials also lends itself to collaboration.

"It's a natural," Predebon says of his fifteen years of research work with Pletka.

"Mechanical engineers tend to look at things at the macroscopic point of view," Predebon says, "but as materials get more sophisticated, we find out we need to include more about the microstructure in our modeling."

The two even co-advise students, who are instrumental to all the successes.

"Just like in industry, where people work in teams," Pletka says, "it's quite appropriate for us to work in teams. Bill [Predebon] always did the mechanics, I always did the processing and the characterization, and [ME-EM Associate Professor Ghatu] Subhash does the high-strain-rate testing and analysis. The student, Alonzo, is working on putting the whiskers into the alumina."

Subhash also focuses on the "why."

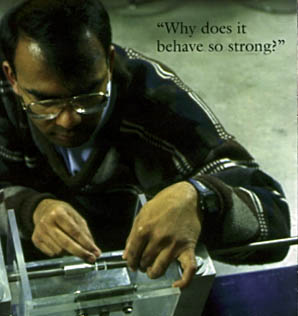

"What I am looking for is the mechanisms that are responsible for this high-strength behavior, he says, "Why does it behave so strong, and, in mechanical properties terms, where would it be more suitable for applications?"

Another student, Satish Venugopalan, is looking at high-temperature properties.

"This cutting tool gets hot," Subhash says, "So he is testing the properties of the alumina up to 1,000oC. It should retain strength properties at the high temperatures."

Analysis of properties under different circumstances is part of Subhash's forte. He uses the example of Silly Putty®, which has tremendous static properties: it can be stretched slowly; but its dynamic properties are such that it snaps when pulled quickly.

Making the complex simple helps Subhash teach. He has even used answers, in the form of questions, to teach precollege kids a la Jeopardy.

In fact, teaching is foremost in all the researchers' minds as they talk about their work.

Predebon tells an interrupting student to "call me tonight at home" to get the information he needs. Pletka's student is immersed in the alumina research-the ultimate hands-on, and Subhash's teaching abilities are revealed in two recent awards: MTU's 1995 Distinguished Teaching Award, and the American Society of Engineering Education's 1996 Outstanding Young Mechanics Educator Award.

Photo above: Ghatu Subhash asks the tough questions.

![]()